3M™ Ceramic Sand Screen Systems

- 3M ID B49000158

Our Sand Control Assessment gives you a free cost-benefit analysis produced by our technical experts at 3M. Your report is completely personalized with site-specific insights to give you an idea of your project’s ROI.

Our apologies...

An error has occurred while submitting. Please try again later...

Thank you!

Your form was submitted successfully

Details

Highlights

- Helps optimize customer's production potential and potentially extend their asset lifecycle management

- Globally field-proven downhole tool that allows for efficient sand control in a wide range of reservoir conditions

- Helps maximize productivity by potentially reducing operation risk while also providing sand-free production

- Compatible with other well equipment to help simplify well condition

- Helps prevent proppant flowback

- Can be applied as a stand-alone screen beyond traditional boundary conditions

- Resists hotspotting during fracturing, chemical stimulations or heterogenous reservoirs

- pH-Neutral material resists corrosion even during workovers and stimulations

- Our 3M ceramic material is 10x harder than metal, offering excellent erosion resistance

3M™ Ceramic Sand Screen Systems are designed to deliver high performance sand control in new wells, workover and intervention applications – both in unconsolidated formations and where proppant flowback poses a risk. This is based on proven, successful and unique technology with deployments globally including subsea deployments, rigless and rig for both well remediation.

-

Enhanced Asset Lifecycle Management

Enhanced Asset Lifecycle Management -

Erosion Resistance

Erosion Resistance -

Increased Productivity

Increased Productivity -

Operational Simplicity

Operational Simplicity

3M has over 100 years of experience working with ceramic materials. Time and expertise have delivered a sand screen material that delivers exceptional resistance to erosion, corrosion, wear and temperatures up to 1800ºC.

-

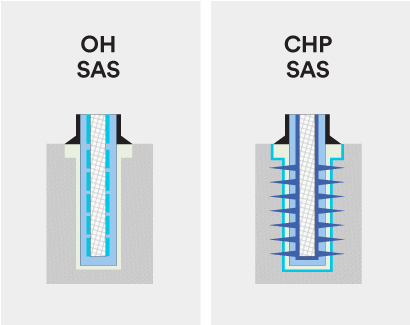

Effective sand control in virtually any system

Whether the wellbore is cased or not, 3M sand screens offer effective and durable protection from flowback that allows the well to remain productive much longer than other screen materials.

This globally proven downhole sand control tool has been successfully applied in cased hole, open hole well completions for green, brown, and marginal fields as new wells, remediation or maintenance of downhole sand control scope for reservoir sands and proppant flowback applications.

-

-

A complete sand control system

A complete sand control system3M™ Ceramic Sand Screen Systems consist of:

- Extremely durable ceramic filter rings

- Pre-perforated base pipe

- Endcaps

- External metallic shroud

-

Performance in a broad range of conditions

Performance in a broad range of conditionsMaterial features V-shaped or keystone slot openings for specific well applications.